Explore Resilient Bobcat Aftermarket Parts for Ideal Equipment Upkeep

Unlocking Possible: Aftermarket Components as a Cost-efficient Solution for Equipment and Heavy Devices

In the ever-evolving landscape of equipment and hefty tools upkeep, the use of aftermarket parts has arised as an engaging alternate worth checking out. While the idea may elevate eyebrows amongst traditionalists, the advantages that aftermarket parts offer in terms of price savings, quality, and efficiency are not to be ignored.

Price Cost Savings and Worth Proposal

The expense financial savings and worth suggestion of utilizing aftermarket parts for machinery and hefty devices are substantial elements that add to operational effectiveness and economic practicality in numerous industries. By going with aftermarket components over initial equipment maker (OEM) components, businesses can recognize significant price savings without jeopardizing on high quality or efficiency. Aftermarket parts are typically extra competitively valued than their OEM counterparts, enabling firms to lower maintenance and repair work costs while still making certain the proper functioning of their machinery and devices.

Additionally, the value recommendation of aftermarket components expands past price financial savings. These components are extensively readily available and supply a broader selection compared to OEM parts, providing businesses with greater flexibility and benefit in sourcing the components they need. Additionally, aftermarket parts are recognized for their top quality and integrity, conference or also surpassing market requirements oftentimes. This reliability translates into improved operational performance and lowered downtime, inevitably improving general productivity and success for organizations that choose to leverage aftermarket solutions for their equipment and heavy equipment needs.

Top Quality and Compatibility Guarantee

When thinking about the usage of aftermarket parts for machinery and heavy devices,Emphasizing the vital importance of quality control and compatibility confirmation is crucial. Ensuring that aftermarket components surpass or fulfill industry requirements for high quality is crucial to keeping the optimum efficiency and long life of the machinery. Quality guarantee actions, such as extensive testing treatments and qualifications, offer confidence to devices owners that the aftermarket components will certainly work dependably and properly.

Raised Accessibility and Alternatives

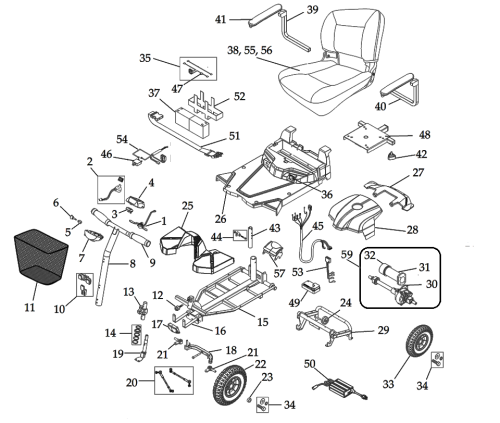

With a broadening market and expanding need, aftermarket components for machinery and hefty devices are currently using enhanced accessibility and a broader variety of alternatives to provide to the diverse needs of equipment proprietors. This surge in schedule is driven by the aftermarket parts market's commitment to satisfying the certain demands of numerous machinery brand names and models. Tools owners can currently access a wide selection of aftermarket parts, ranging from engine elements to hydraulic components, electric systems, undercarriage components, and extra.

Additionally, aftermarket components suppliers are continuously increasing their item lines to include parts for a broader series of equipment and heavy tools, making certain that proprietors can discover appropriate replacements despite the tools type or model they possess. This raised schedule and range of aftermarket parts encourage equipment owners to make affordable decisions without compromising on quality or efficiency. As an outcome, they can effectively maintain, repair, and upgrade their machinery with confidence, understanding that aftermarket parts provide a dependable option to OEM elements.

Efficiency and Longevity Advantages

Enhancing equipment and heavy tools with aftermarket components brings remarkable performance and resilience advantages to devices proprietors. Aftermarket components are commonly made with advancements in innovation and materials, offering enhanced efficiency contrasted to original tools supplier (OEM) components. Upgraded elements can cause raised power, efficiency, and general maker abilities, bring about boosted productivity and operational efficiency.

Additionally, aftermarket components are often crafted to be extra durable and sturdy than their OEM counterparts. This raised toughness can translate to reduced downtime for maintenance and repairs, inevitably conserving tools owners valuable time and money. By buying aftermarket components understood for their toughness, machinery and hefty equipment can withstand harsh operating problems and heavy work with greater durability.

Essentially, the efficiency and durability advantages of aftermarket components contribute significantly to enhancing the capability and long life of machinery and hefty tools. Devices proprietors stand to acquire an affordable edge by leveraging aftermarket remedies to boost the general efficiency and durability of their properties.

Sustainability and Ecological Influence

The use of aftermarket parts not only improves the performance and toughness of equipment and heavy devices yet additionally plays a crucial duty in addressing sustainability concerns and decreasing environmental impact. By opting for aftermarket components, industries contribute to the decrease of waste generation because you could look here these components are usually sourced from recycled products or through remanufacturing processes. This technique lines up with the principles of a round economic situation, where resources are utilized effectively, and waste is lessened.

Additionally, aftermarket parts can extend the life-span of machinery and equipment, read this article reducing the frequency of replacements and subsequently decreasing the total carbon impact related to manufacturing brand-new machinery. Additionally, the production of aftermarket components usually includes less power intake and less discharges compared to manufacturing initial tools producer (OEM) components - Bobcat Aftermarket Parts. This transition to aftermarket components sustains eco-friendly techniques by promoting reusability and resource conservation within the industrial industry. Ultimately, the combination of aftermarket components into equipment repair and maintenance is a lasting approach that profits both businesses and the setting.

Verdict

To conclude, aftermarket parts supply an economical service for equipment and hefty tools by giving expense savings, quality control, boosted availability, efficiency advantages, and sustainability advantages. These components not just supply a sensible option to original devices producer parts however additionally add to the total efficiency and durability of machinery and tools. Accepting aftermarket parts can bring about considerable price savings and boosted performance, making them a useful option for services looking to maximize their sources.

By opting for aftermarket parts over initial equipment maker (OEM) components, businesses can recognize significant cost savings without endangering on quality or performance (Bobcat Aftermarket Parts). Devices proprietors can now access a broad selection see this site of aftermarket parts, ranging from engine elements to hydraulic components, electric systems, undercarriage components, and a lot more

In addition, aftermarket parts producers are continually increasing their product lines to include parts for a wider variety of equipment and hefty tools, guaranteeing that owners can discover appropriate substitutes no matter of the tools kind or model they possess. Aftermarket parts are commonly made with developments in innovation and products, offering improved efficiency contrasted to original devices supplier (OEM) components. In addition, the manufacturing of aftermarket components usually entails much less power intake and less discharges contrasted to producing initial devices producer (OEM) parts.